Background

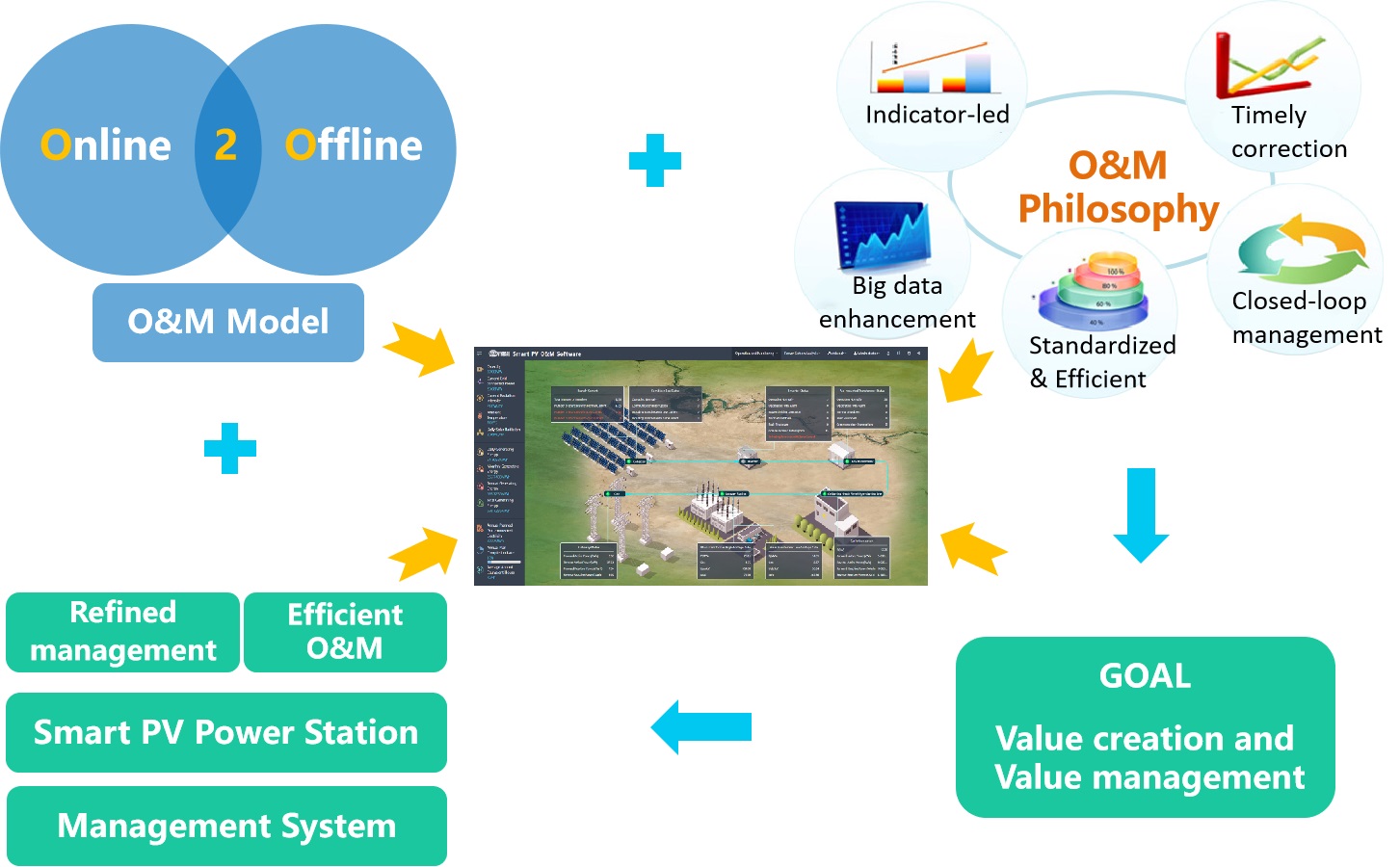

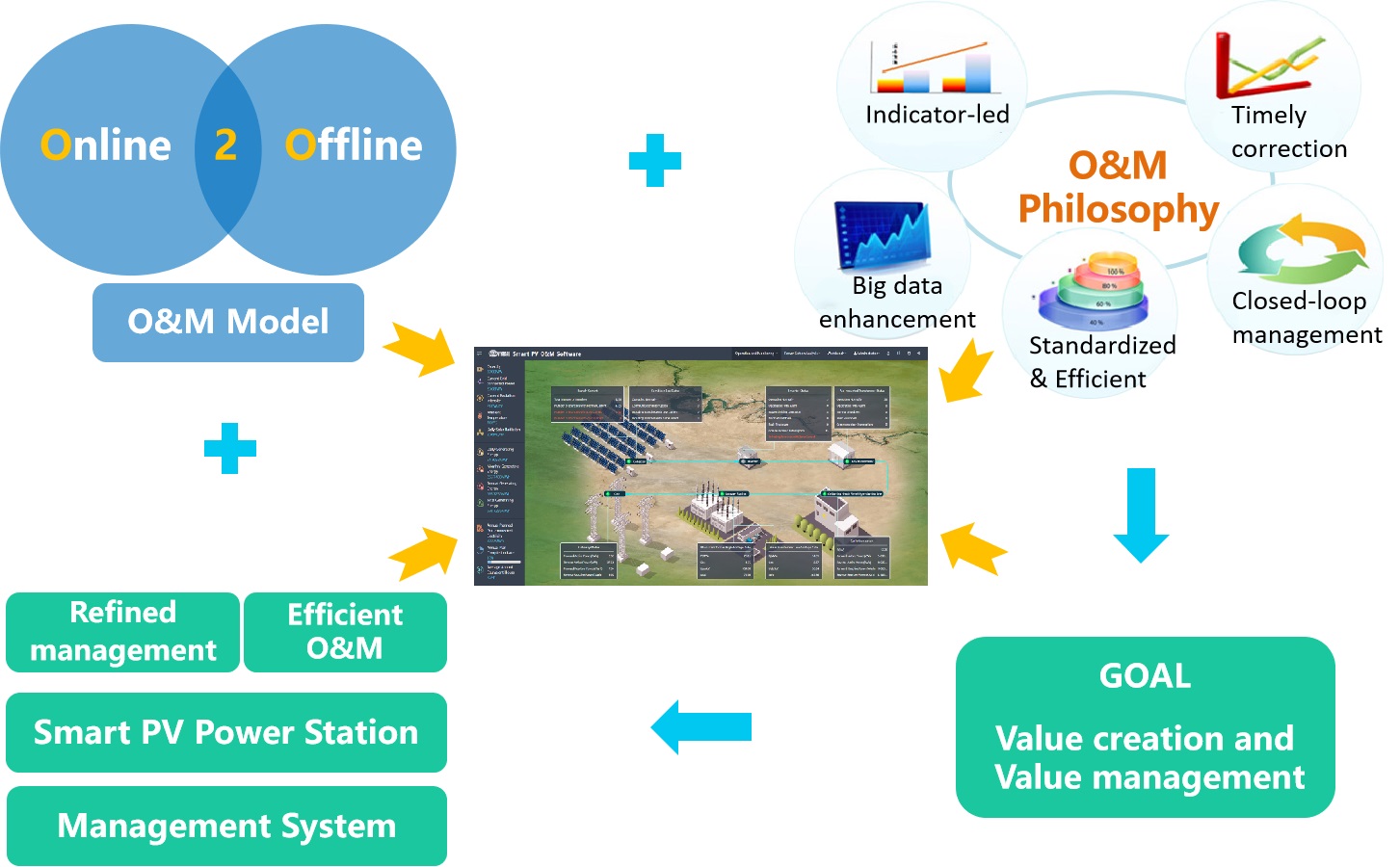

To address a series of challenges faced by photovoltaic (PV) power stations, such as large areas, numerous equipment, time-consuming and labor-intensive inspections, shortage of operation and maintenance (O&M) personnel, long life cycles, low efficiency of traditional monitoring systems in fault localization, and the lack of comprehensive and detailed analysis on equipment operation data and station performance, which in turn fails to guide the O&M staff to perform efficient maintenance, Beijing Millennium Software Co., Ltd. (referred to as "MLN") has developed a Smart PV O&M Software. This software guides station management personnel to apply advanced scientific management concepts and leverages an intelligent information management system to monitor and supervise the station's O&M work timely and conveniently, quantify the production process and profits, continuously optimize management, and increase targeted profits. It aids O&M personnel in completing their tasks safely, standardly, and efficiently through an intelligent information system, ensuring the stable and efficient operation of the station.

Product Features

MLN Smart PV O&M Software is the first technological software in China for the unified digital and intelligent management of PV power stations. It has been successfully applied in multiple large-scale PV power stations, such as Geermu, Longyangxia, etc.

1.Real-time Monitoring: Enables real-time monitoring of the operational status of station equipment.

2.Equipment Historical Analysis: Maintenance personnel can conduct a comprehensive analysis of inverters through historical data, from aspects such as equivalent loss hours, equipment utilization, inverter equivalent hours, and equipment alarms. This helps in pinpointing inverters with poor generation levels. Further analysis of inverter units (inverter + combiner box + branch) identifies hidden defects for preventative maintenance and establishes a closed-loop management system for defect and contact orders.

3.Station Performance Analysis: Management personnel can analyze factors affecting station performance, such as overall efficiency, completion rate of planned output, abandoned power due to maintenance, faults, grid limitations, equivalent loss hours, solar resources, and inverter performance. This ensures the station's stable and efficient operation.

4.Energy Consumption Analysis: Management can conduct a comprehensive analysis of factory electricity consumption, purchased grid electricity, total factory consumption, and collection line energy consumption. Optimizing the living electricity usage of station personnel and equipment energy consumption reduces operational costs and enhances station benefits.

5.Solar Resource Analysis: Managers can analyze actual radiation, researchable radiation, and resource distribution maps to understand the real situation of an area, providing a reliable basis for investment, design, and equipment selection.

6.Defect Management: Station chiefs can use intelligent real-time fault alerts to categorize defects, arrange for rectification, and track progress, ensuring complete and effective defect resolution and improving efficiency.

7.Fault Resolution Solution: Maintenance personnel can categorize and systematize encountered operational problems, solidifying handling methods and processes to improve fault resolution efficiency and standardization. This not only shares maintenance experience but also enhances the overall operational level of the station.

8.Inverter Energy Distribution: Station management can analyze the power curve and DC current comparison of all station inverters.

9.Branch Current Discreteness: Management can perform a comparative analysis of the branch current discreteness of all station inverters on a daily basis.

Core Value

Ensure the safe, standardized, and efficient operation of PV power station with builtin standard operating procedures.

Ensure power generation with smart alert, Automatic fault localization, high efficiency in defect elimination.

Increase power generation with analysis of the power station from comprehensive performance, identify potential hazards, handle them in advance.

Achieve sustained high-level operation and maintenance of power station with scientific indicator evaluation system.

Improve operational efficiency with Automatic statistical reports, freeing up manpower.

Access the station's status in real-time from anywhere, keeping you are always in control.